The entire process chain of

bakery technology – think process!

We are a company of the WP BAKERYGROUP, which means we cover the entire process chain of bakery technology for all purposes ranging from fi nest artisan to large industrialized production, for fresh and durable baked goods. We are the only supplier in the industry with that all-round capability, making us market leader in the fi eld, worldwide. We produce everything the market needs. We have been working for bakers and have been for a long time. We are successful in what we do. Because our customers - bakers all over the world - are successful with our products. We are always looking for the better solution, the better technology, the better product. We follow the markets and their requirements.

![Mixer UC PRO [Translate to Englisch:]](/fileadmin/_processed_/5/8/csm_WP-Kemper_Wendelkneter-UC-PRO-t_24b9e85e15.png)

![Mixer SP [Translate to Englisch:]](/fileadmin/_processed_/b/e/csm_WP-Kemper_Spiralkneter-SP-t_e374ec2bd1.png)

![Mixer KRONOS digital [Translate to Englisch:]](/fileadmin/_processed_/1/5/csm_WP-Kemper_Spiralkneter-KRONOS-digital-t_e9c2c13d59.png)

![Mixing system AUTOMATIC TITAN [Translate to Englisch:]](/fileadmin/_processed_/6/7/csm_WP-Kemper_Knetsystem-AUTOMATIC-TITAN-t_e01d60d6ac.jpg)

![Mixer POWER MIXER [Translate to Englisch:]](/fileadmin/_processed_/d/0/csm_WP-Kemper_Bodenentleerungskneter-POWER_MIXER-t_d3cefdba54.png)

![Mixing system POWER ROLL SYSTEM [Translate to Englisch:]](/fileadmin/_processed_/a/8/csm_WP-Kemper_Knetsystem-POWER-ROLL-SYSTEM_t_99083112f3.jpg)

![Mixing system TITAN LINEAR SYSTEM [Translate to Englisch:]](/fileadmin/_processed_/d/c/csm_WP-Kemper_Knetsystem-TITAN-LINEAR-SYSTEM-t_2fe374d393.jpg)

![Mixing system POWER SQUARE SYSTEM [Translate to Englisch:]](/fileadmin/_processed_/3/7/csm_WP-Kemper_Knetsystem-POWER-SQUARE-SYSTEM-t_6a892843a2.jpg)

![Bowl tipper HK 150 [Translate to Englisch:]](/fileadmin/wpkemper/produktwelt/hk-150/WP-Kemper_Hebekipper-ueberkopf-HK150-t.jpg)

![Automatic deep fryer L2000 A [Translate to Englisch:]](/fileadmin/_processed_/2/4/csm_WP-Riehle-Linie2000A_2_65dfb4021b.png)

![DLA Industry Touch [Translate to Englisch:]](/fileadmin/_processed_/8/1/csm_WP-Riehle_DLA_industry-touch_74c2867c9a.jpg)

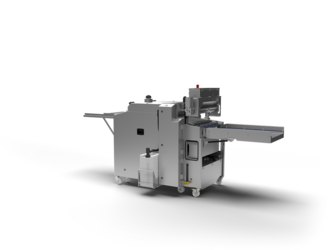

![Lye application machine RMBB [Translate to Englisch:]](/fileadmin/_processed_/4/4/csm_WP-Riehle_RMBB_1a131ed6cc.png)

![Lye application machine COMJET [Translate to Englisch:]](/fileadmin/_processed_/a/4/csm_WP-Riehle-Comjet_879be66ea8.jpg)

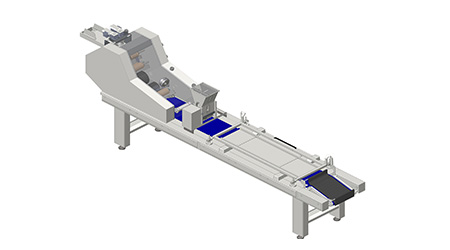

![Lye application machine ALLROUND [Translate to Englisch:]](/fileadmin/_processed_/c/b/csm_Allround_2020_ablegeband_2_frei_6fefa8df54.png)

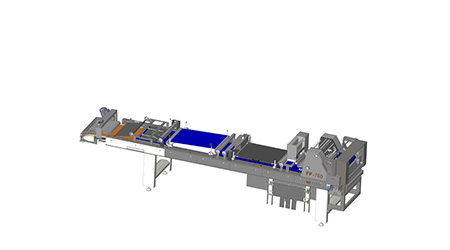

![Lye application machine ALLROUND Peelboard [Translate to Englisch:]](/fileadmin/_processed_/4/5/csm_WP-Riehle_Allround_peelboard_5fb65e0a5c.png)

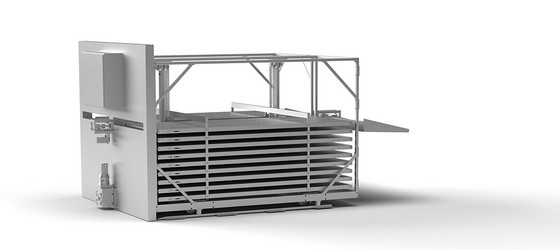

![Vacuumcooling VACUSPEED® artisan [Translate to Englisch:] Abbildung der Vakuumkühlzelle VACUSPEED® artisan](/fileadmin/_processed_/1/b/csm_WP-Vacuumkuehlung-VACUSPEED_248f65122e.jpg)

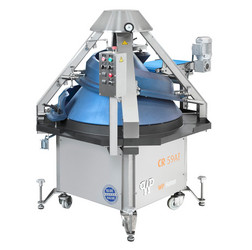

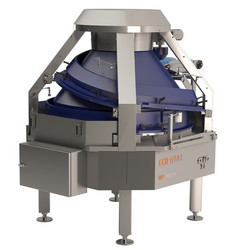

![Shop glazer system REVOLUTION [Translate to Englisch:]](/fileadmin/_processed_/f/4/csm_Shop-Glasierer-System_10b90483c2.jpg)

![Tray cleaning unit Multi-Clean [Translate to Englisch:]](/fileadmin/_processed_/8/b/csm_WP-Riehle_BWM_gesamt2_73c7aa97ed.jpg)

![Blechreinigungsgerät BRM DELUXE [Translate to Englisch:]](/fileadmin/_processed_/2/9/csm_WP-Riehle_BRMDeluxe__2__b0e6fe12df.jpg)